Key Takeaways

- Manual processes in the supply chain lead to delays and higher costs.

- AI-powered data extraction enables real-time visibility across operations.

- Automated document workflows reduce inventory issues and order errors.

- AI helps identify supply chain risks before they escalate.

The Costly Reality Of Manual Supply Chains

The automotive supply chain is a highly intricate network involving thousands of moving parts, both literally and figuratively. From supplier invoices and purchase orders to shipping manifests and customs forms, managing the flow of information across departments, vendors, and systems is no small task.

BayInfotech reported that a mid-sized federal agency handling over a million documents annually sees employees spending up to 30% of their time on manual admin tasks like data entry and verification. That adds up to thousands of hours lost to repetitive work.

Yet, despite massive technological advances, many organizations still rely on outdated, manual processes to handle this critical documentation. These outdated workflows contribute to order delays, inventory imbalances, and increased labor costs. Over time, this directly impacts customer satisfaction and profitability. AI-driven forecasting can reduce forecast errors by 20–50% and lead to up to 65% fewer stockouts, along with 5–10% lower warehousing costs and 25–40% lower administrative costs compared to traditional methods, according to McKinsey, showing just how impactful automation can be when applied strategically.

Fortunately, tools like Parseur offer a smarter way forward. By automating document data extraction and seamlessly integrating it into supply chain systems, Parseur helps businesses move faster, reduce costs, and unlock valuable insights from their documents without the manual drag.

For a deeper look into how document processing automation is already reshaping the automotive landscape, check out our complete guide on AI-powered Document Processing In The Automotive Industry.

Critical Challenges In The Automotive Supply Chain

Automotive supply chain managers face increasing pressure to move faster, reduce costs, and maintain precision at every step. However, legacy systems and manual processes create major roadblocks that slow operations and introduce costly errors.

As reported by the SDC Executive, nearly 55% of automotive manufacturers still rely on manual processes for critical quality and documentation tasks, which shows the industry's ongoing risk of errors, delays, and mounting operational inefficiency.

Here are some of the most common pain points:

Errors in invoice and purchase order matching

Manual entry mistakes can result in mismatched records, delayed payments, and strained supplier relationships.

Inventory inaccuracies

Incomplete or outdated data often causes stockouts or overstock situations, hurting sales and tying up capital.

Late detection of shipment delays

Without real-time visibility, teams cannot respond quickly to disruptions, resulting in missed delivery windows and production bottlenecks.

Delayed risk mitigation

Identifying supplier reliability issues or contract non-compliance manually takes too long, exposing companies to preventable risks.

These challenges are not isolated. They compound over time, leading to increased operational drag and missed opportunities. For supply chain leaders, adopting smarter tools is no longer optional. It is essential for staying competitive.

How AI And Data Analytics Transform Supply Chain Efficiency

Artificial intelligence and data analytics are revolutionizing supply chain operations, especially in the data-heavy automotive industry. By converting documents into structured data, businesses can unlock a level of visibility and control that is simply not possible with manual workflows.

According to All About AI, 87% of enterprises use AI for demand forecasting, resulting in a 35% improvement in accuracy, while 67% report a 28% reduction in stockouts through AI-based inventory management

AI tools can extract, analyze, and act on data in real time. This means supply chain managers can make faster and more informed decisions based on historical trends and live input.

Accurate demand forecasting

AI models can analyze past invoices, order history, and regional trends to predict future demand with higher precision. This reduces excess inventory and minimizes stockouts.

Real-time anomaly detection

Irregularities in invoices or shipping documents, such as unexpected pricing or missing items, are flagged immediately, helping teams resolve issues before they cause downstream delays.

Supplier performance tracking

Data extracted from delivery notes and compliance reports can be automatically evaluated to identify late shipments or inconsistent quality, allowing for smarter vendor management.

This is where Parseur plays a central role. By automatically extracting structured data from documents like invoices, shipping manifests, and purchase orders, Parseur ensures that AI systems have high-quality input for analysis. Instead of relying on error-prone manual entry, Parseur turns unstructured documents into JSON data that can be instantly sent to your analytics or ERP platforms.

The result? Faster cycle times, better insights, and less wasted time.

Practical AI Solutions For Supply Chain Risk Identification & Mitigation

Supply chain disruptions can stem from various issues, such as unexpected price hikes, late shipments, or contractual non-compliance. By extracting and analysing data from supply chain documents, AI systems can detect risk signals early and enable proactive decision-making.

For example, companies using AI-based risk management have seen a 30% reduction in revenue losses and a 50–70% faster time to identify disruptions, according to Everstream Analytics, showing clear evidence of how data-driven systems help teams stay ahead of crises.

By extracting and analyzing data from supply chain documents, AI systems can detect risk signals early and enable proactive decision-making. Here are a few practical ways automotive supply chains are using AI to stay ahead of disruptions:

Invoice pattern monitoring

AI tools can scan invoice data and flag unusual changes in pricing, quantity mismatches, or invoice frequency. For instance, if a supplier suddenly raises prices by 10% on a single line item, the system can trigger a review before payment is processed.

Shipment delay alerts

By parsing freight documents and carrier updates in real time, AI systems can spot delayed shipments based on expected versus actual departure or delivery times. This allows teams to reroute orders or adjust production schedules quickly.

Contract compliance tracking

AI-powered document processing can extract and monitor specific clauses from supplier contracts. If a vendor fails to meet agreed-upon terms, such as delivery timelines or quality standards, procurement teams can receive alerts immediately.

Supplier scoring models

Using AI, companies can create dynamic scoring systems based on supplier performance. Metrics such as delivery reliability, invoice accuracy, and compliance rate are updated automatically using real-time extracted data.

These applications help supply chain leaders reduce risk exposure and build stronger, more transparent vendor relationships. With tools like Parseur supplying the clean, structured data needed for this analysis, implementing AI-based risk mitigation becomes both practical and scalable.

How Parseur Simplifies Document Automation In Your Supply Chain

Automating supply chain documents doesn't have to be complicated or require coding skills. Parseur provides a user-friendly, low-code solution that allows automotive companies to extract and structure data from documents instantly and reliably.

Here’s how it works:

Document collection

Send documents such as invoices, purchase orders, and shipping notices to a dedicated Parseur email inbox or connect via API.

AI-driven data extraction

Parseur’s intelligent engine automatically detects and extracts relevant fields, like invoice numbers, supplier names, PO details, shipment dates, and line items, without manual setup. This speeds up processing and ensures flexibility across various document formats.

Structured data output

After extraction, Parseur automatically formats the data into structured outputs like JSON, CSV, or Excel, ready for reporting, analysis, or system integration.

Seamless Integration

The structured data can be sent in real time to your ERP, TMS, or logistics software using Webhooks, Zapier, Make, or API integrations. Parseur works smoothly with platforms like SAP, Oracle, and QuickBooks, ensuring continuity with your current tools.

By making document automation simple and scalable, Parseur empowers automotive supply chain teams to process high volumes of paperwork faster, with fewer errors and less manual work.

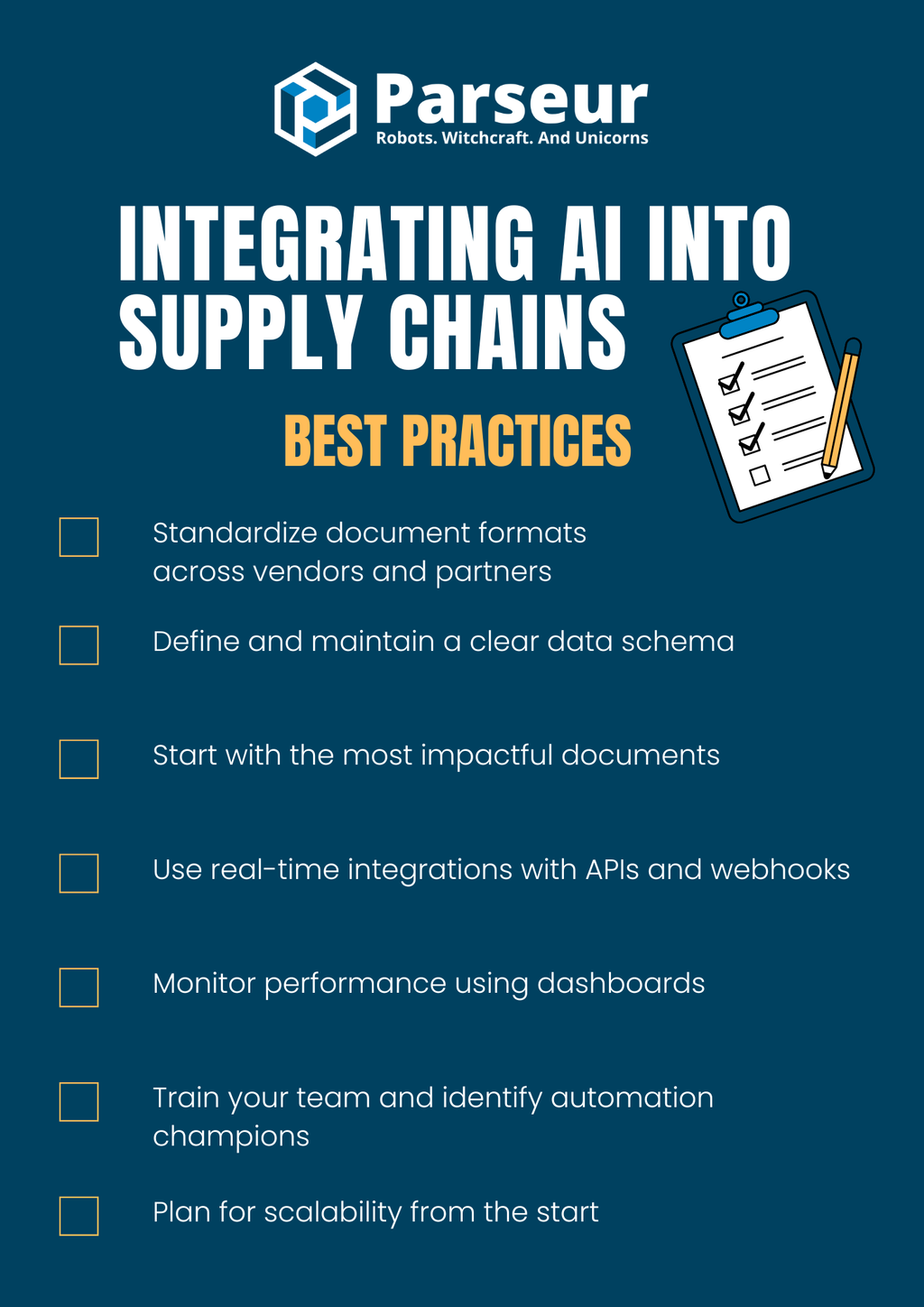

Best Practices For Integrating AI Document Processing Into Supply Chains

Integrating AI-powered document automation into your supply chain requires more than adopting a new tool. A strategic approach is important to maximize efficiency, reduce costs, and build long-term reliability.

According to PwC’s 2025 Digital Trends Survey, 53% of supply chain professionals are already using AI tools to anticipate and mitigate supply chain disruptions, with an additional 31% piloting similar solutions.

Below are essential best practices to guide a smooth and impactful implementation.

Standardize document formats across vendors and partners

Automotive supply chains often work with dozens or even hundreds of vendors and logistics providers. These partners may each send documents in different layouts and formats. Encourage vendors to follow standardized formats for key documents like invoices, shipping manifests, and purchase orders. This will simplify the template creation process and increase the accuracy of automated data extraction.

Define and maintain a clear data schema

Before automating extraction, it’s important to know exactly what data you need and how it should be structured. Define a consistent data schema that covers invoice numbers, payment terms, delivery addresses, SKUs, order quantities, and other relevant fields. A clear structure ensures that parsed data can seamlessly enter your ERP, inventory management, or financial systems without manual intervention.

Start with the most impactful documents

Begin your automation journey by targeting the documents that generate the most administrative workload or are prone to the highest error rates. Typically, these include supplier invoices, freight documents, and purchase orders. Automating these first steps allows your team to see immediate improvements in processing time and accuracy while building internal confidence in the system.

Use real-time integrations with APIs and webhooks

Once documents are parsed, the data should flow directly into your existing supply chain systems without delay. Parseur makes it easy to set up real-time data transfers using webhooks, APIs, Zapier, or Make. This allows your operations team to respond to issues quickly, whether they’re price discrepancies, shipment delays, or missing PO references.

Monitor performance using dashboards

Ongoing monitoring is essential for optimizing document automation. Parseur’s built-in dashboard offers visibility into processing metrics, errors, and exception handling. Regularly reviewing this data allows teams to refine extraction templates, correct recurring issues, and improve performance over time. The dashboard becomes a central hub for continuous improvement.

Train your team and identify automation champions

To ensure adoption and long-term success, invest in training the team members responsible for handling supply chain documents. Provide hands-on guidance for editing templates, reviewing parsed data, and resolving exceptions. You can also identify internal champions who can lead optimization efforts, support peers, and promote automation adoption within the organization.

Plan for scalability from the start

As your business grows, document volume will increase, and new suppliers or logistics providers will be added. Design your workflows to scale easily by creating reusable templates, organizing documents by mailbox, and leveraging Parseur’s ability to handle large volumes. Planning for future complexity ensures your automation remains sustainable.

By implementing these best practices, automotive companies can reduce bottlenecks, improve operational visibility, and build a supply chain that is resilient, responsive, and ready for the future.

Proven ROI: Real-World Benefits Of Supply Chain AI Automation

AI-powered document processing enhances workflows and delivers measurable financial and operational results. By automating data extraction and document handling, automotive companies can reduce overhead, speed up supply chain cycles, and make more informed decisions.

One of the biggest advantages is the reduction in document processing time. Manual entry and verification can take hours per document across high-volume operations. With tools like Parseur, documents are processed in seconds and routed instantly to the correct systems.

Administrative costs tied to document handling also decrease significantly. On average, Parseur customers save approximately 189 hours of manual data entry per month, representing a 98 percent reduction, which equates to over USD 90,000 annually.

Improved forecasting accuracy means companies can lower inventory carrying costs and avoid overstock or shortages. Additionally, early anomaly detection, like delayed shipments or billing mismatches, allows teams to respond faster and avoid costly disruptions.

The bottom line: when implemented strategically, AI document processing drives speed, savings, and supply chain resilience.

Looking Ahead: The Future Of AI In Automotive Supply Chains

The future of AI in the automotive supply chain is already taking shape, driven by advancements in automation, connectivity, and intelligent systems. As supply chains become more digitized, we’ll see broader adoption of tools that can process not just structured text, but also images, voice data, and sensor outputs.

Technologies like IoT and blockchain are being integrated with document automation to ensure greater transparency and real-time tracking of parts, shipments, and supplier compliance. Meanwhile, multimodal AI is enabling more accurate decision-making by combining visual data (like shipment photos) with extracted document insights.

Looking even further ahead, conversational AI and predictive analytics will play an even larger role. Imagine supply chain managers using a chatbot to ask, “What shipments are at risk this week?” and getting instant responses based on current document and sensor data.

Tools like Parseur position automotive companies to take advantage of these changes. With automated data extraction at their core, they serve as the foundation for next-generation supply chain intelligence.

Next Steps: Implementing AI Now

The automotive supply chain is evolving rapidly, and businesses that continue relying on manual processes risk falling behind. By embracing AI-powered document processing, supply chain leaders can significantly cut administrative overhead, reduce errors, and gain real-time visibility into operations.

Platforms like Parseur make this transformation simple. With its no-technical-knowledge-required setup, powerful extraction engine, and seamless integrations, Parseur empowers teams to unlock the value hidden in their documents.

Want to understand the full potential of AI-powered document automation in automotive? Read our guide on AI-powered Document Processing In The Automotive Industry for an in-depth exploration.

Last updated on